The CircleHealth project focuses on reducing the use of virgin plastics and textiles in the healthcare sector while promoting circular practices. Although some progress has been made at leading hospitals, no organized or systematic efforts have been established until now. Currently, 6% of Denmark’s greenhouse gas emissions come from healthcare, and public procurement for circular products remains underdeveloped.

The project aims to map and analyze plastic and textile waste across the healthcare value chain, with the goal of reducing CO2 emissions. This involves designing products, adjusting consumption patterns, and using public procurement to drive innovation. By improving the way materials are managed, the project seeks to transform waste into valuable resources, reducing the environmental impact of healthcare.

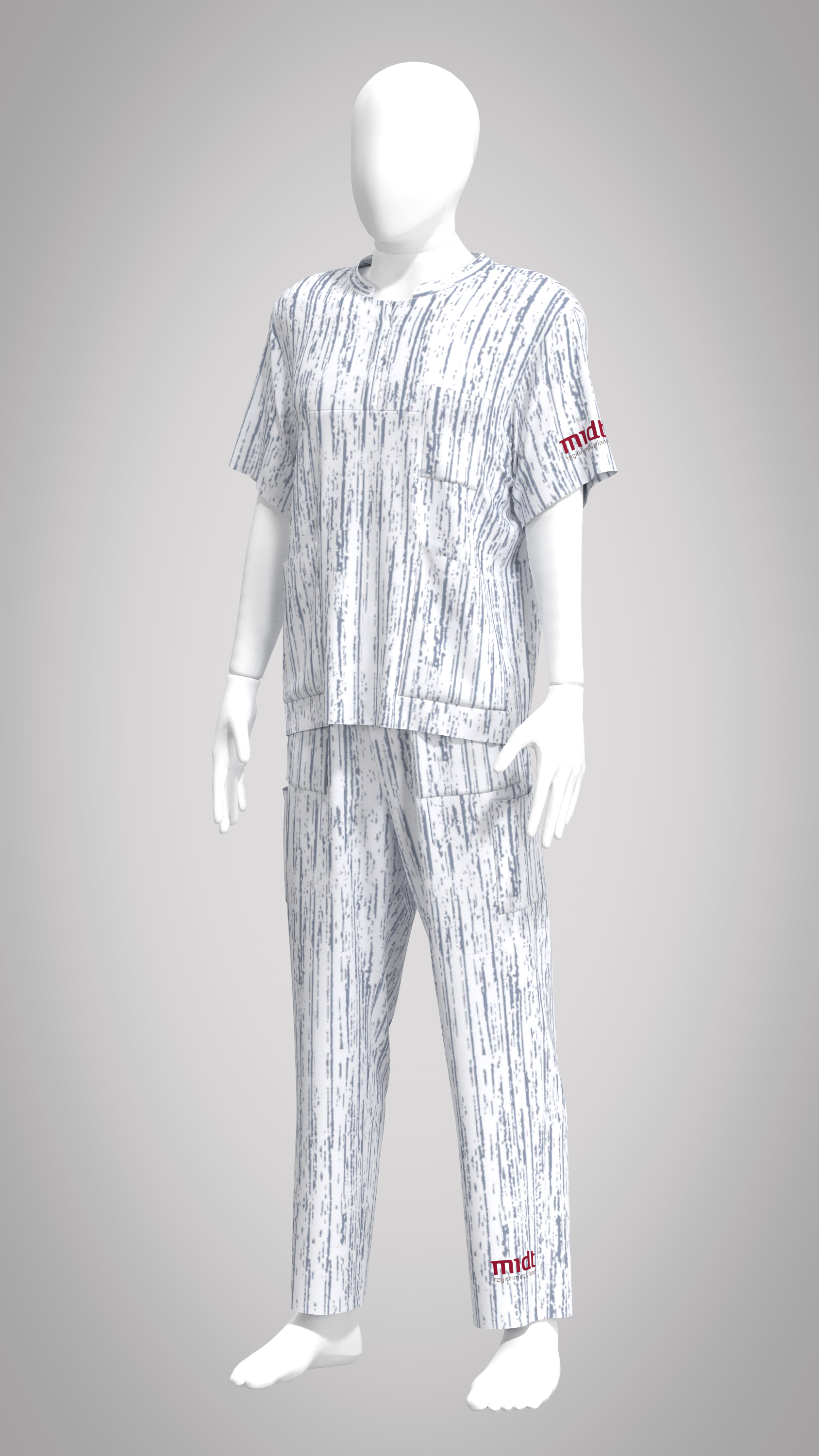

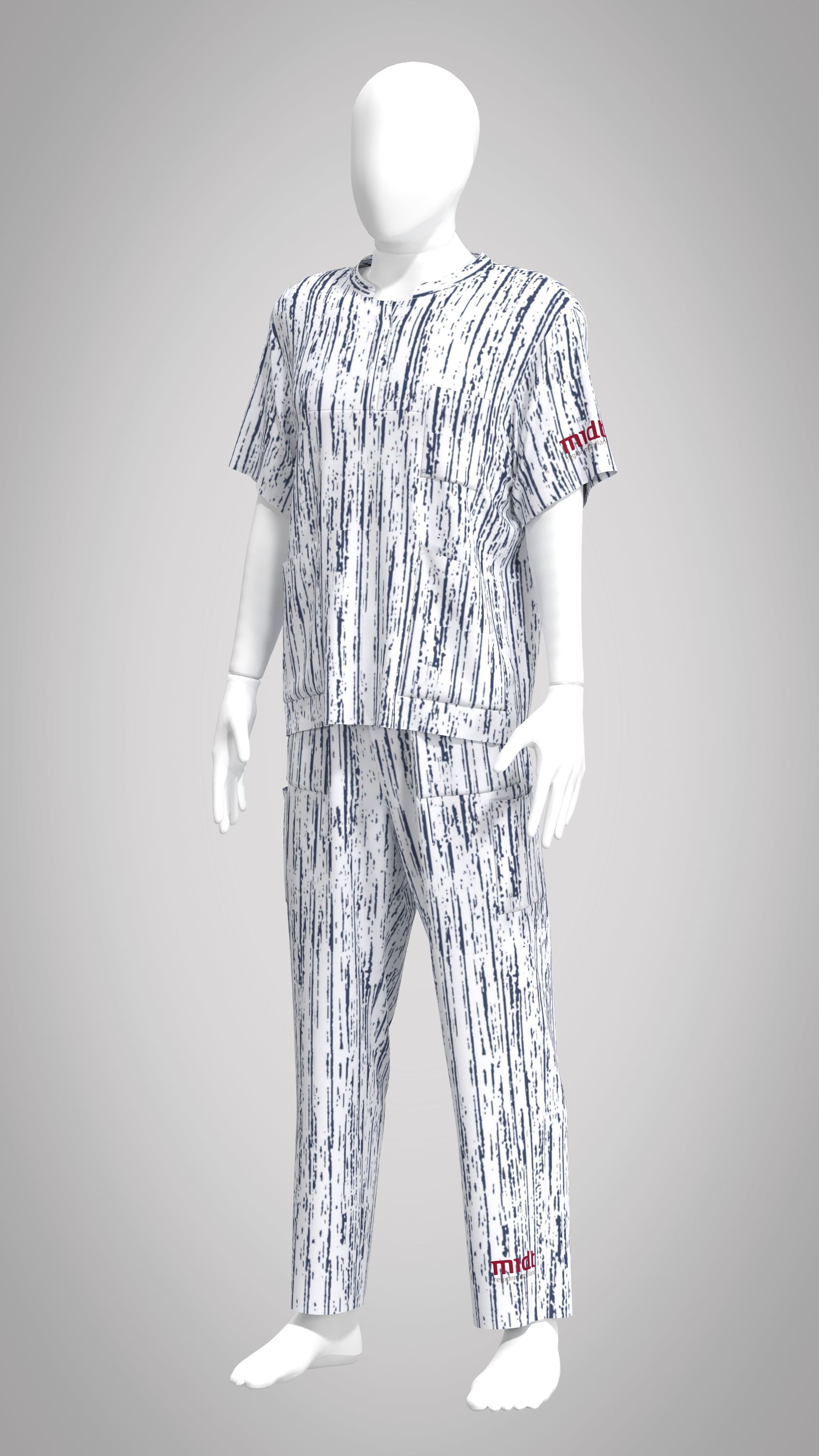

This is a four-year project, and I contributed during the first six months, focusing specifically on hospital uniforms. Our goal was to improve their design to make them more durable, easier to repair, and longer lasting, reducing the need for frequent replacements.

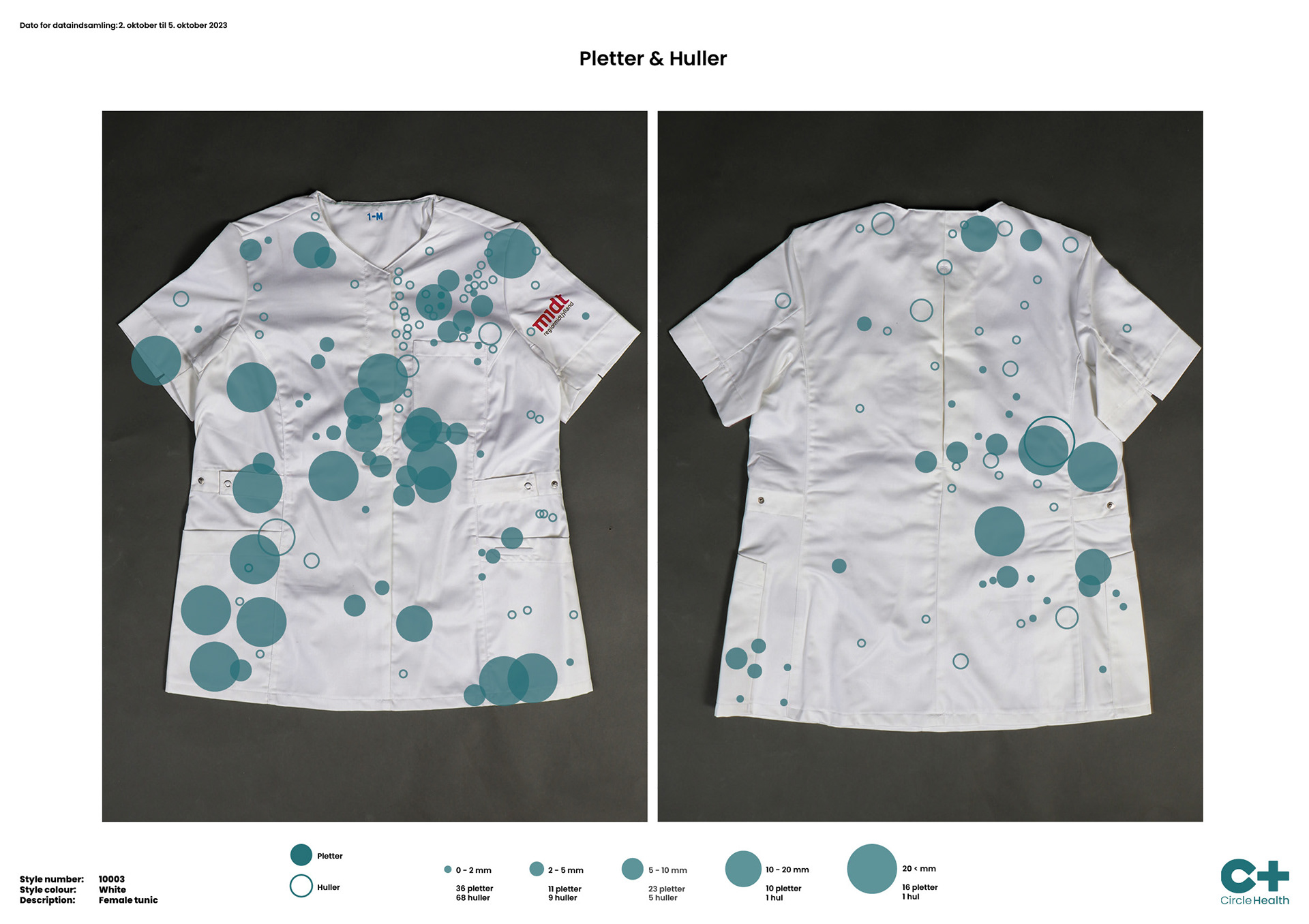

One of my first tasks in this project was to map out the common areas where holes and stains appear on hospital uniforms. To do this, I examined a week's worth of uniforms sent for cleaning, analyzing around 400 garments. Through this process, I identified a variety of patterns in wear and tear, providing valuable insights for improving the durability and repairability of the uniforms.

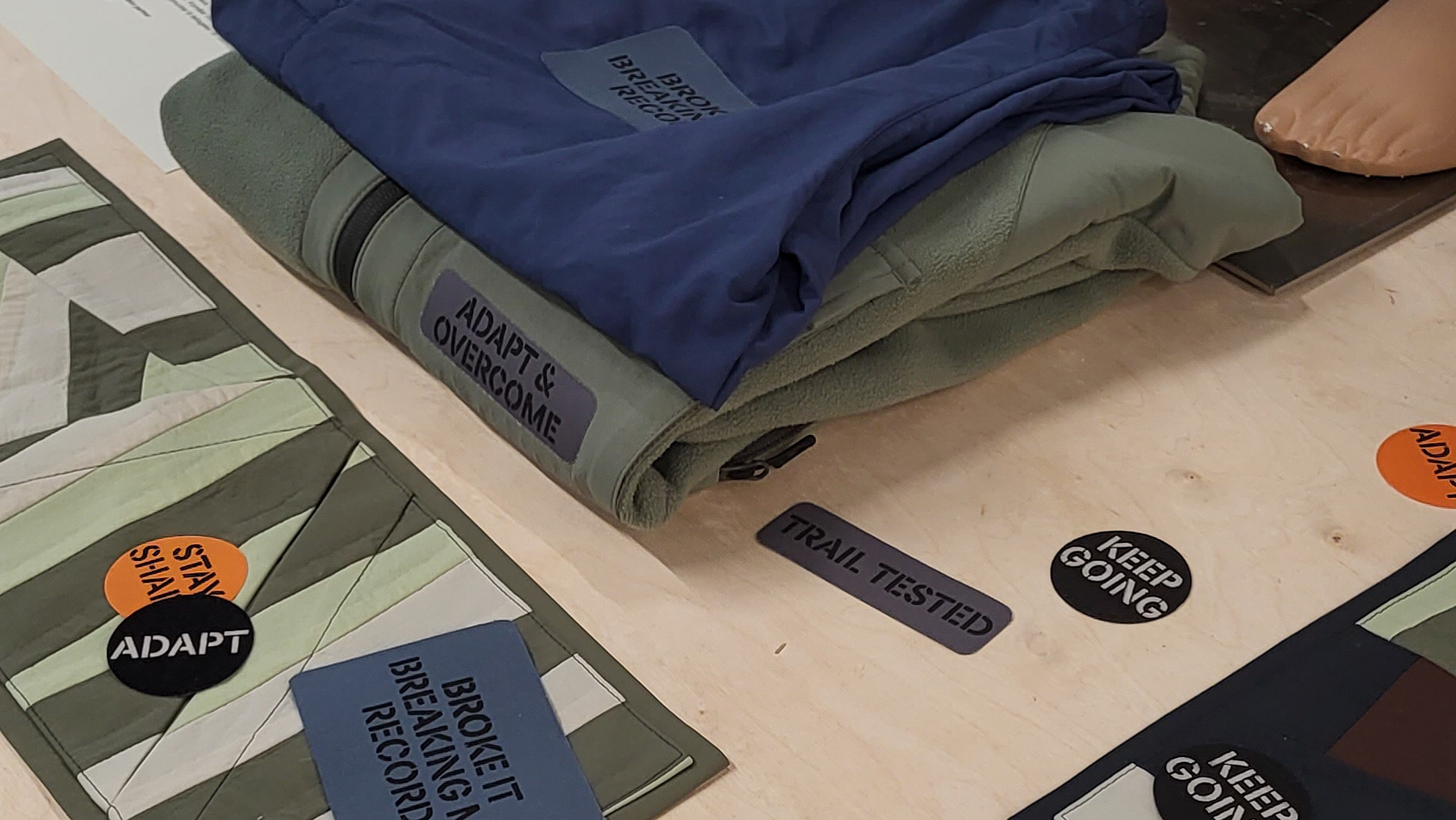

Next, I developed several repair solutions for the stains and holes, experimenting with a range of techniques—some more visible than others. I explored different approaches, varying in time, detail, and visibility, to determine what worked best for different areas of the uniforms based on the type of damage. This experimentation was essential in finding the most suitable repair methods for each specific issue.

We visited Aarhus Hospital to test our ideas directly with the doctors and nurses who wear the uniforms daily. We gathered feedback on color preferences, repair solutions, and quality control. This experience was invaluable, providing us with practical insights into what would work best in a real-world setting.